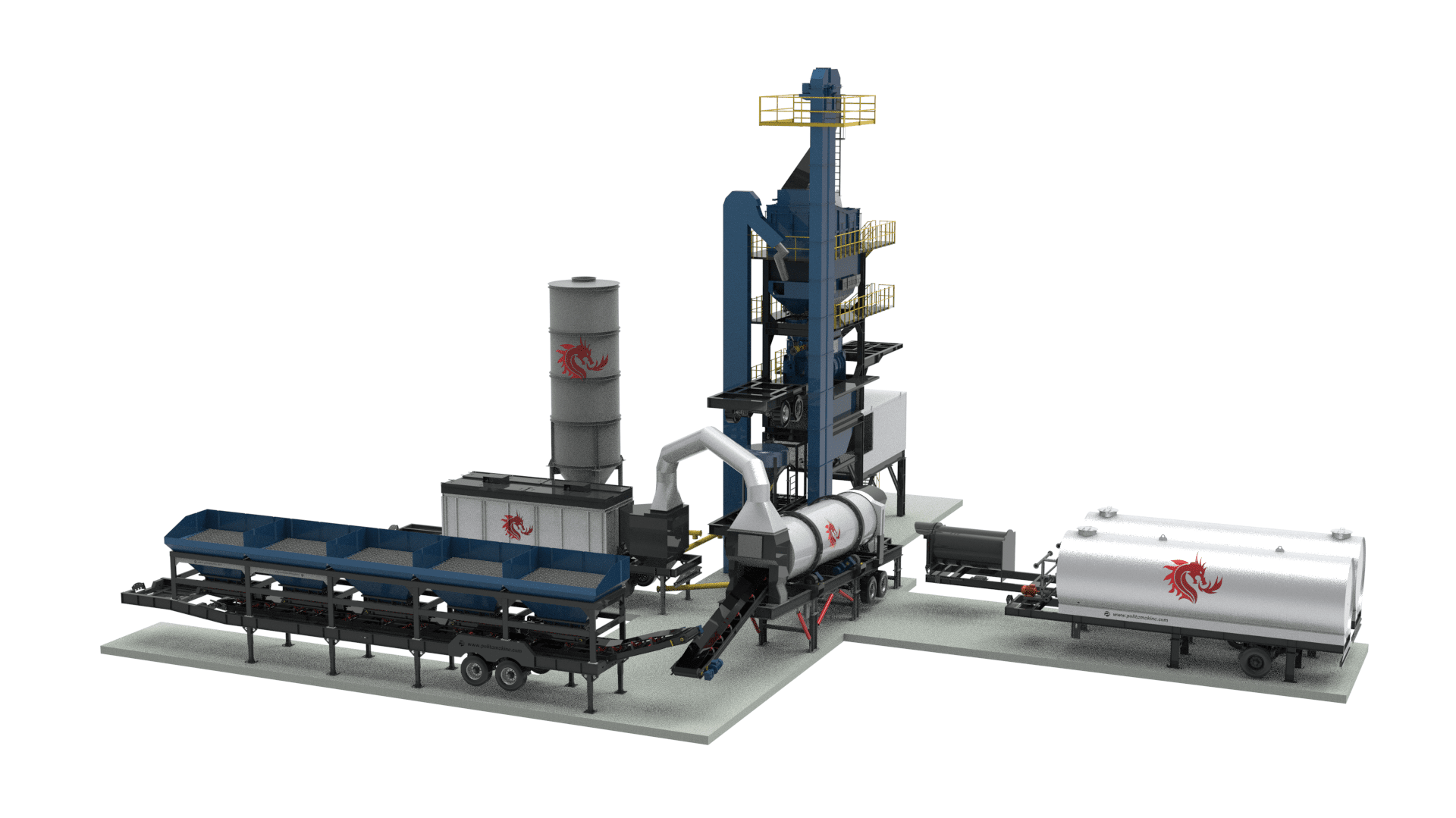

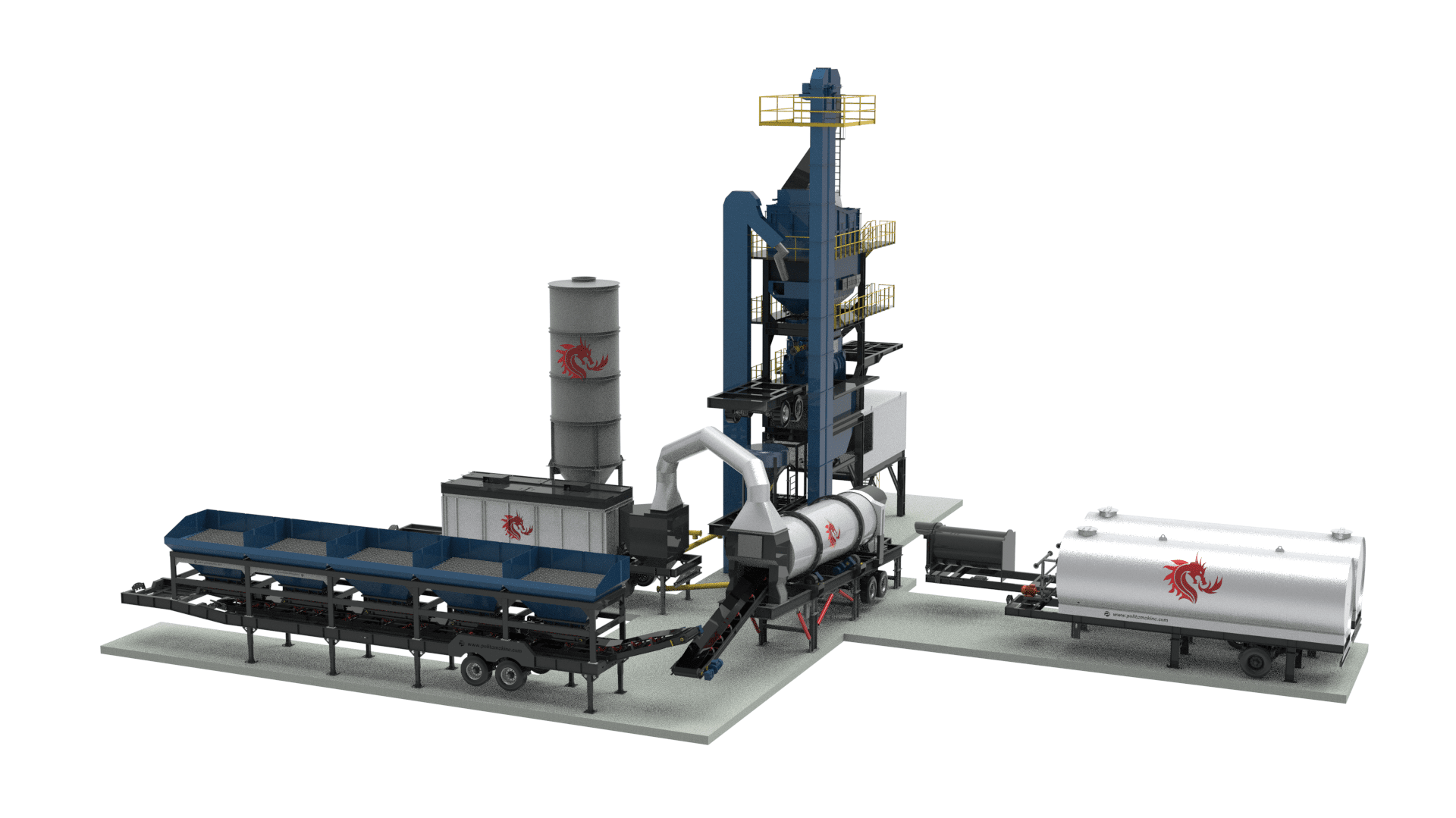

STATIONARY ASPHALT PLANT

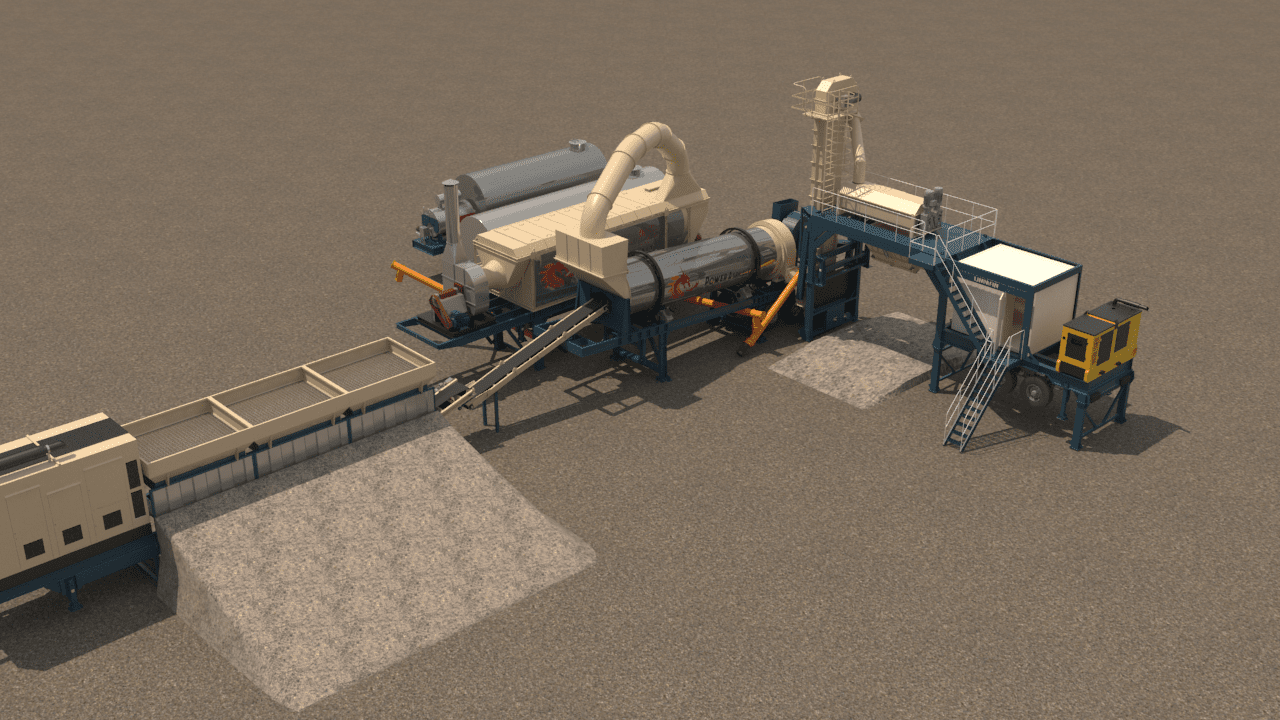

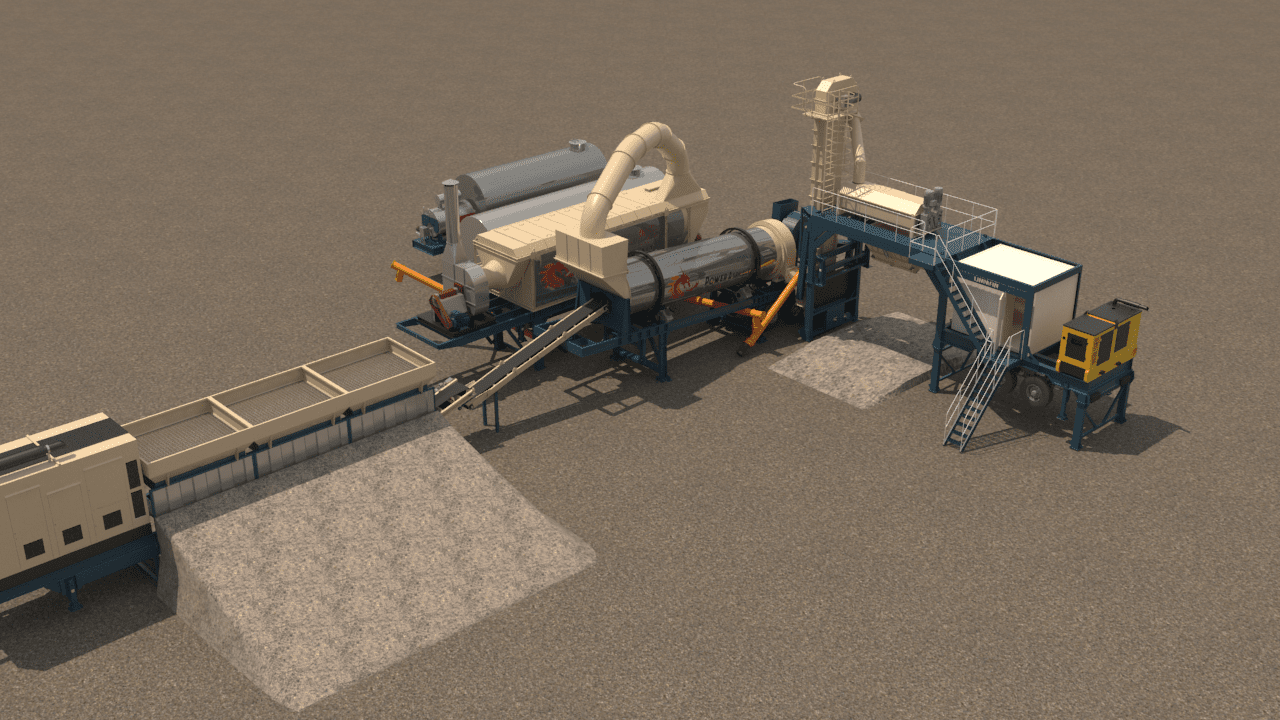

MOBILE ASPHALT PLANT

![]()

Power Asphalt Plant

T +90(312) 394 19 90

Email: info@powerasphalt.com

Power Asphalt Plant Technologies

1341.Cad. No:71 İvedik OSB, 06768, ANKARA, TR

Bins can be selected in the range of 8-25 m³ according to the customer's request. Each bin has a grid to prevent aggregates with a large diameter from being included in the system. Dosing conveyors are frequency controlled. Aggregate feeding is done according to the recipe entered into the software. A vibromotor is used in order to prevent the fine aggregate from getting stuck in the bin. It can also be produced in 4-5-6 fractions according to the customer's request.

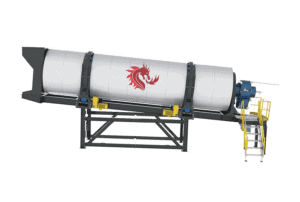

Dryers of Power Asphalt are extremely efficient. Robust, compact and energy-efficient designs minimize maintenance requirements and reduce fuel consumption. Italian production burner is used. It offers the possibility of working with gas, diesel or heavy oil. Body and inner blade materials are resistant to heat and abrasion. Rings are manufactured as one piece (without welding) from special forged steel. Ring and roller surfaces are hardened, providing long-lasting use.

Elevator buckets have high heat and abrasion resistance. Special forged steel chains are used in elevators. They have a completely sealed body. Design for easy assemble has being provided. Back-locked gearboxes are used as a precaution against power cuts. The soft starter system is also used as a precaution against lifting at the first or on load.

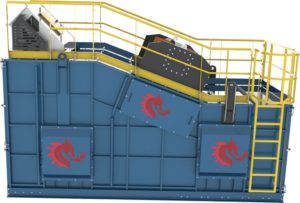

Power asphalt plant vibrating screens sift hot aggregate in an extremely efficient way. It is environment friendly due to dust-proof body structure. Screens are offered in a wide range of options with 4-5-6 fractional designs. Due to design it is easy to maintain.

Power asphalt plant vibrating screens sift hot aggregate in an extremely efficient way. It is environment friendly due to dust-proof body structure. Screens are offered in a wide range of options with 4-5-6 fractional designs. Due to design it is easy to maintain.

For more information, you can review our Asphalt Plant Vibrating Screen article.

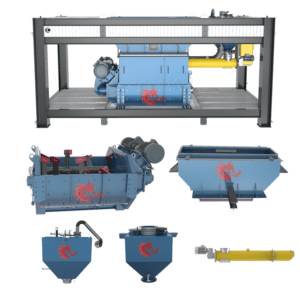

Power asphalt twin shaft mixers provide homogeneous asphalt mixture in a short time. Gearboxes are mounted to work synchronously and are suitable for heavy-duty conditions. Mixer castings are manufactured in a way that is resistant to wear and heat, and can be easily changed.

Power asphalt twin shaft mixers provide homogeneous asphalt mixture in a short time. Gearboxes are mounted to work synchronously and are suitable for heavy-duty conditions. Mixer castings are manufactured in a way that is resistant to wear and heat, and can be easily changed.

For more information, you can review our Asphalt Plant Mıxer article.

Aggregate, filler and bitumen scales are designed for precise weighing. Delicate weighing is carried out according to the required recipe in the software. Bitumen scale is equipped with electrical resistances against cooling and insulated against heat losses. Filler scale works with vibromotor against clogging. Filler and bitumen outlet flaps are made of heat resistant material. Aggregate scale has double cover and is designed to quick discharge.

Aggregate, filler and bitumen scales are designed for precise weighing. Delicate weighing is carried out according to the required recipe in the software. Bitumen scale is equipped with electrical resistances against cooling and insulated against heat losses. Filler scale works with vibromotor against clogging. Filler and bitumen outlet flaps are made of heat resistant material. Aggregate scale has double cover and is designed to quick discharge.

For more information, you can review our Asphalt Plant Weighing Unit article.

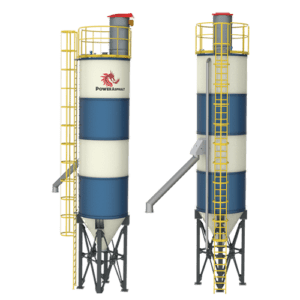

The airflow has been optimized through a highly technical analysis. Modern technology of the bag house with reverse air flow offers up to 3 times bag life compared to jet pulse system, as well as low energy consumption. Metaaramid filter bags are resistant to high temperatures and have a long wear life. The driver-controlled fan system provides lower energy consumption and easier use. The bag house body with a pre-separator reduces the filter load by 50%. The isolation system minimizes temperature losses and prevents sudden cooling, preventing blockages and oxidation in the bag house.

More information, you can review our Asphalt Plant Dust Filter article.

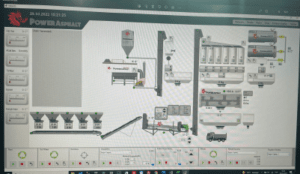

The PowerControl scada program allows the asphalt plant to be used automatically, semi-automatically or manually. It has the feature of reporting and saving historical reports. In case of malfunction, it gives information about the cause of the errors. It offers unlimited number of recipes and customer saving options. In addition, Turkish, English, French, Russian, Arabic language options are available. Due to the use of the global components, it is easy to supply parts in every country. The remote access feature provides the opportunity to identify and solve malfunctions 24/7, from anywhere with the help internet connection.

The PowerControl scada program allows the asphalt plant to be used automatically, semi-automatically or manually. It has the feature of reporting and saving historical reports. In case of malfunction, it gives information about the cause of the errors. It offers unlimited number of recipes and customer saving options. In addition, Turkish, English, French, Russian, Arabic language options are available. Due to the use of the global components, it is easy to supply parts in every country. The remote access feature provides the opportunity to identify and solve malfunctions 24/7, from anywhere with the help internet connection.