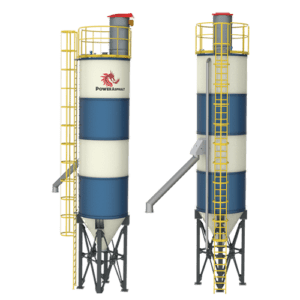

Power Asfalt produces stationary asphalt plants with capacities of 80-320 ton/hour.

- European quality production

- Designs suitable for small, medium and large scale road projects according to the customer's needs

- Fast installation opportunity with its modular structure

- Eco-friendly filter system and long-lasting metaaramid bags

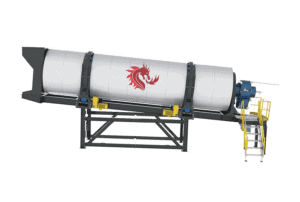

- Fuel-saving burner and dryer

- Long-lasting wear parts

- Fast spare parts supply as a result of production with global components

- 7/24 service and remote connection support

- Additives (modified bitumen plant, fiber additive plant, etc.) and recycling unit can be added easily.

Français

Français  Русский

Русский  العربية

العربية  Türkçe

Türkçe

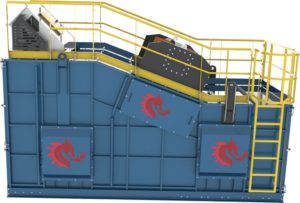

Power asphalt plant vibrating screens sift hot aggregate in an extremely efficient way. It is environment friendly due to dust-proof body structure. Screens are offered in a wide range of options with 4-5-6 fractional designs. Due to design it is easy to maintain.

Power asphalt plant vibrating screens sift hot aggregate in an extremely efficient way. It is environment friendly due to dust-proof body structure. Screens are offered in a wide range of options with 4-5-6 fractional designs. Due to design it is easy to maintain.

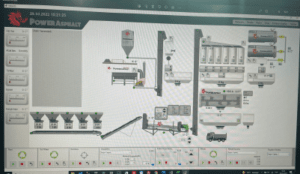

The PowerControl scada program allows the asphalt plant to be used automatically, semi-automatically or manually. It has the feature of reporting and saving historical reports. In case of malfunction, it gives information about the cause of the errors. It offers unlimited number of recipes and customer saving options. In addition, Turkish, English, French, Russian, Arabic language options are available. Due to the use of the global components, it is easy to supply parts in every country. The remote access feature provides the opportunity to identify and solve malfunctions 24/7, from anywhere with the help internet connection.

The PowerControl scada program allows the asphalt plant to be used automatically, semi-automatically or manually. It has the feature of reporting and saving historical reports. In case of malfunction, it gives information about the cause of the errors. It offers unlimited number of recipes and customer saving options. In addition, Turkish, English, French, Russian, Arabic language options are available. Due to the use of the global components, it is easy to supply parts in every country. The remote access feature provides the opportunity to identify and solve malfunctions 24/7, from anywhere with the help internet connection.