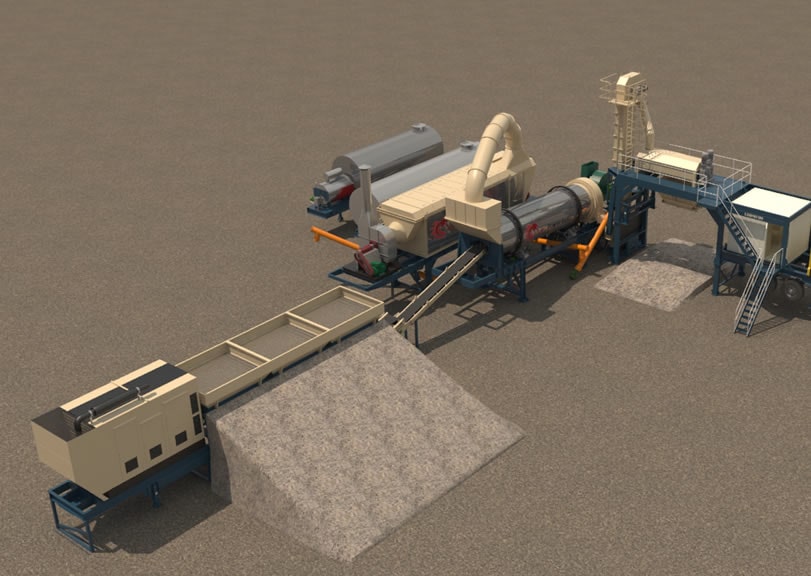

Continuous type asphalt plants; They are preferred with their prominent features such as easy installation, low initial investment cost, and low maintenance costs. Power continuous type asphalt plant; It is produced as mobile or fixed in capacity ranges of 80-240 tons per hour.

Highlights

Mobility and high capacity combined

- Asphalt production on mobile or stationary chassis in 80-240 tons/hour capacity

- Minimum crane requirement

- Quick assembly

- Minimum cost of concrete foundation

High quality hot asphalt production

- Mixing in a double-shaft continuous mixer outside of the dryer

- Precise dosing of bitumen, aggregate and filler

- Double shaft mixer providing high homogeneity and long wear resistance

Efficient fuel consumption

- Excellent heat transfer between aggregate and flame

- Italian burner quality and proportional fuel burning technology

- Heat insulated dryer

User-friendly software

- PowerControl software system

- Automatic and manual use feature

- Full control of production

- User-friendly interface and multi-language support

- Possibility of immediate intervention to the malfunction thanks to the remote connection specification.

Eco-friendly and new technology filter

- Dust-free environment with low emission values

- Long bag life with bags made of metaaramid material

- Low energy consumption and low maintenance costs with reverse air flow system

- Low fuel consumption with burner-filter communication system

Français

Français  Русский

Русский  العربية

العربية  Türkçe

Türkçe